In the field of door and window hardware, although hinges are "small components", they play a crucial role in ensuring the smooth operation, safety, and service life of doors and windows. WEINI has always focused on the research and development of damping hinges with the core concept of "craftsmanship", and has continuously refreshed the industry's perception of the performance of "small components" through continuous technological iterations. The newly launched 4-inch 18.5 split-type damping hinge is another practical achievement of the brand's concept of "empowering details with technology".

Looking back at the R&D history of WEINI's damping hinges, the 6-inch split-type damping hinge once gained recognition in the market for its innovative structural design and stable performance. However, WEINI did not stop at its existing achievements. Instead, it aimed at the industry challenge of "balancing miniaturization and high performance" and launched a new round of technological breakthroughs. The R&D team went through countless blueprint revisions, repeatedly optimizing everything from the overall structure of the hinge to the size parameters of each component. At the same time, through more than a thousand performance tests, they simulated the opening and closing status, load-bearing capacity, and durability of the hinge in different usage scenarios, and continuously adjusted the technical solutions. Finally, the team successfully controlled the hinge shaft diameter to an accurate 18.5mm, fully condensing the key performances of the 6-inch hinge, such as core damping function and stable load-bearing, into a compact 4-inch size. This new product not only conforms to the minimalist and lightweight aesthetic trend of modern doors and windows, but also achieves an all-round breakthrough in technology, confirming WEINI's product evolution logic of "reducing size while increasing technology". A smaller shaft diameter means higher requirements for component precision, structural rationality, and material performance, which is a direct reflection of the new product's technical strength.

Traditional damping hinges often face long-standing problems such as poor durability, oil leakage risks, and difficult maintenance during long-term use. WEINI's 4-inch 18.5 split-type damping hinge solves these pain points one by one through three core technological innovations.

Firstly, the pioneering split-type linkage structure. The force transmission path of traditional hinges often has design flaws, leading to high friction loss between components. After long-term use, problems such as stuck opening/closing and abnormal noise are prone to occur. WEINI's new product optimizes the structural layout and creates a split-type linkage design, allowing the force to be more evenly transmitted to each component during the opening and closing of the hinge, significantly reducing the friction coefficient between parts. This design not only makes the opening and closing of the hinge smoother, but also significantly improves its durability, achieving a qualitative leap in service life compared with traditional products.

Secondly, the adoption of oil-free power design. Hydraulic damping hinges rely on hydraulic oil to achieve the buffering effect, which is prone to oil leakage after long-term use. This not only pollutes the surface of the door and affects its appearance, but also causes the damping function to fail, making the hinge lose its buffering effect. WEINI's new product completely abandons the traditional hydraulic structure and innovatively adopts an oil-free power system, allowing the power components to operate independently and fundamentally eliminating the possibility of oil leakage. This design not only ensures the cleanliness of the door body, but also guarantees the long-term stability of the damping function, greatly improving the reliability of use.

Thirdly, the integration of a detachable and replaceable integrated damper. The buffering performance is the "soul" of a damping hinge. However, the damper of traditional hinges is mostly fixedly connected to the overall structure. Once the buffering function fails, the entire hinge often needs to be replaced, which not only increases the use cost but also brings a lot of inconvenience. The integrated damper of WEINI's new product completely changes this situation: each damper undergoes a full inspection before leaving the factory to ensure uniform and delicate buffering effect, avoiding the problem of uneven opening and closing speed. At the same time, the damper adopts an independent modular design and can be disassembled and replaced separately. Even if the buffering function fails later, ordinary people can replace the damper by themselves according to simple guidelines without the need for professional maintenance personnel, completely solving the trouble of "replacing the entire hinge when one part is broken" of traditional hinges.

In addition, the power system of the new product has also been fully upgraded. The precise 7mm stroke design ensures more stable and long-lasting power output, avoiding the problem of weak opening and closing caused by power attenuation after long-term use. Equipped with an 11.6mm piano wire high-energy storage spring, it not only ensures uniform door-closing force to make the door close smoothly, but also the spring supports independent disassembly and replacement. Even if the spring ages, there is no need to replace the entire hinge, fundamentally reducing maintenance costs and extending the overall service life of the hinge.

WEINI's 4-inch 18.5 split-type damping hinge not only achieves breakthroughs in technology, but also fully considers the actual needs of users in terms of design, achieving "comprehensive functions and convenient operation" and becoming an "all-round" hinge product suitable for diverse scenarios.

In terms of functional adaptability, the new product supports free switching between first-stage force and second-stage force. By adjusting the preload screw insertion depth on the hinge, users can flexibly choose the appropriate door-closing force mode according to the weight of the door/window and the usage scenario (such as household entrance doors, indoor wooden doors, fire doors in commercial places, etc.). The first-stage force mode is suitable for lighter doors and windows, making opening and closing more lightweight; the second-stage force mode is suitable for heavier doors and windows to ensure more stable closing. This design allows one hinge to meet the needs of different types of doors and windows, greatly expanding the product's adaptation range.

At the same time, the new product innovatively integrates four core functions: door closing, hinge, door stop, and positioning. When installing traditional doors and windows, it is often necessary to install multiple accessories such as hinges, door stops, and positioners separately, which not only increases the purchase cost but also prolongs the installation time, and there may be compatibility issues between different accessories. Through an integrated design, WEINI's new product combines four core functions. Users only need to install this one hinge to realize the smooth opening and closing of the door/window, automatic door closing, positioning to prevent shaking, and door stop fixing. This saves the trouble of additional purchase and installation of accessories, greatly improving installation efficiency and user convenience.

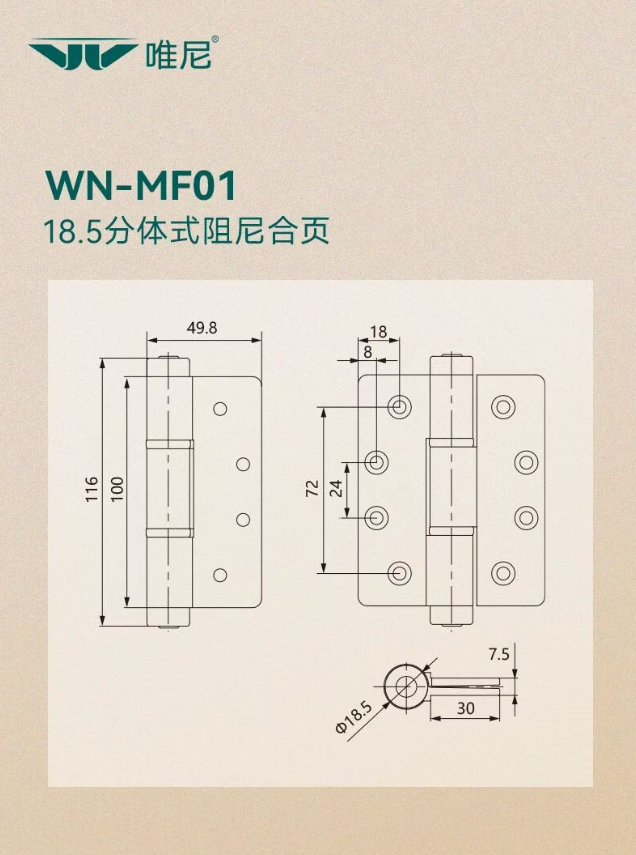

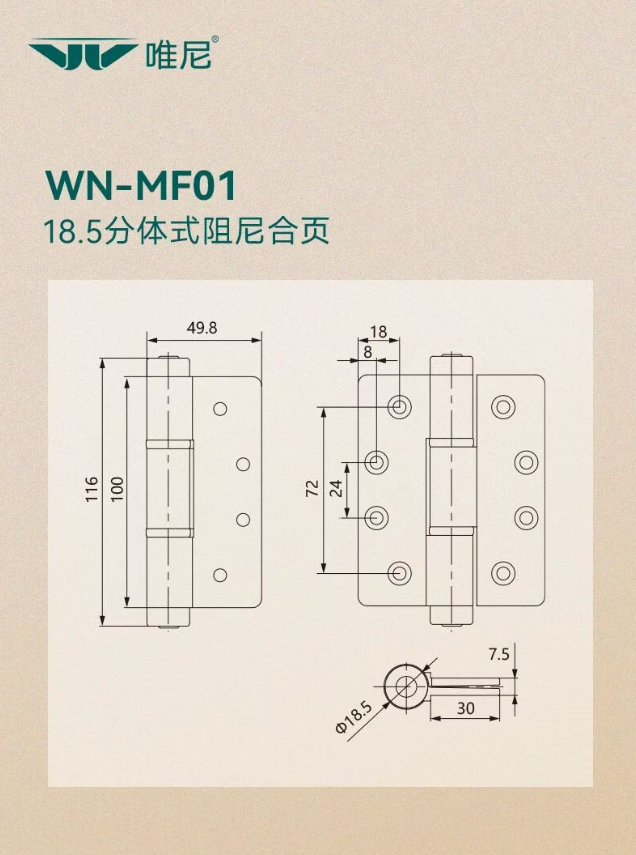

In terms of performance parameters, the new product also demonstrates the characteristics of "small size with great power": the leaves are made of space aluminum, which has both lightweight and high-strength advantages. Each hinge weighs only 186g but can achieve a load-bearing capacity of 25kg, ensuring that the door/window is not easily deformed or sagged during long-term use. After strict life testing, the new product can achieve 150,000 opening and closing cycles without failure. Calculated based on the daily use frequency of a family (20 times a day), the service life can exceed 20 years. In terms of environmental adaptability, the new product can operate stably in a wide temperature range of -30℃ to 60℃. Whether in the cold northern regions or the hot and humid southern regions, it can maintain excellent performance and is widely suitable for various materials and types of doors and windows such as fire doors, solid wood doors, entrance steel doors, and aluminum alloy doors.

In terms of after-sales experience, WEINI also starts from the user's perspective to create a "worry-free maintenance" system. In addition to the detachable and replaceable damper and spring mentioned earlier, other core components of the hinge also adopt a modular design, which is convenient for users to conduct daily inspections and replacements. At the same time, the brand provides clear maintenance guide manuals and video tutorials. Even ordinary people without professional maintenance experience can easily complete maintenance operations, greatly reducing the subsequent use and maintenance costs. From product design to after-sales support, WEINI has always taken "user needs" as the core, making "easy to use, durable, and worry-free" the standard of the product.

From the market verification of the 6-inch hinge to the technological breakthrough of the 4-inch 18.5 split-type damping hinge, WEINI has not only achieved product iteration and upgrading, but also redefined the industry benchmark for buffer hinges with the concept of "small components, great craftsmanship". In the future, WEINI will continue to deepen its focus on the hardware field, develop more high-quality products with continuous technological innovation and the ultimate pursuit of details, empower every door and window, and allow users to experience the great convenience and high quality brought by "small components" in their daily lives.