v

-

Soft Close Drawer Slide Rail Damper

Silent Closures That Actually Feel Good – No More Slamming! This isn’t just “quiet” – it’s the kind of soft close that makes you go, “whoa, that’s nice.” It soaks up the energy from closing doors/drawers, so no more loud slams waking up the kids or disrupting a quiet office. Your furniture feels fancier, and your space stays peaceful – total win. Install in Minutes – No Fussy Tools Required! Forget hunting for random parts or borrowing a drill. The HF-011 and HF-012 kits come with all the stuff you need: brackets, springs, screws – everything. You don’t need to be a pro to put it together, and it cuts installation time in half. Manufacturers and DIY folks both love this. No More Messy Oil Leaks – We Fixed That Annoying Problem! Traditional hydraulic buffers leak oil, right? Stains your drawer liners, ruins furniture – super frustrating. Our top-notch sealing tech locks oil in for good. No more mess, no drop-off in performance. Finally, a buffer that doesn’t make a mess of your stuff. Fits All Your Furniture – Super Versatile! It works with indoor sliding doors (stops them from slamming into frames), big drawers (keeps your stuff inside safe and extends rail life), and even luxury cabinets – thanks to the HF-S35 single-spring buffer, which is made just for those fancy three-section ball bearing rails. One buffer, so many uses. Works Anywhere – Hot, Cold, Doesn’t Phase It! Whether you’re up north where it freezes (-45°C!) or down south where it’s sweltering (+50°C), this buffer keeps going. No weird jolts, no slowdowns – it performs like it’s in a perfect climate, no matter the weather. Tough as Nails – Lasts Forever (Okay, 50k+ Uses!) This thing doesn’t break easy. It handles up to 50KGS, and lasts over 50,000 cycles – way more than you’ll use it in daily life. We test every single one with strict checks (thanks to our ERP system) and tough material tests, so you know it’s reliable. Made with Stuff That Doesn’t Wear Out – POM + More! We don’t skimp on materials. The core parts are POM – a tough engineering plastic that resists impacts, doesn’t age fast, and keeps friction low. Need extra strength? HF-007B has a stainless steel shell (no warping!), and HF-10B mixes POM with metal – light but strong. We’ve Got Your Back – 10+ Years of Trusted Support! This isn’t some fly-by-night product. Hongfeng Zhiyang has been doing damping tech for over a decade, with solid pre-sales help and after-sales support. Furniture brands worldwide use us because they know we deliver. When you pick our buffer, you’re picking a brand that stands behind its stuff.

Premium Soft Close Drawer Slide Rail Damper: Silent & Smooth Closing Solution Ultra-Quiet Soft Close Drawer Slide Rail Damper for Enhanced User Experience High-Performance Soft Close Drawer Slide Rail Damper: Durable & Noise-Free Innovative Soft Close Drawer Slide Rail Damper: Redefine Drawer ClosingEmail Details -

Adjustable Hydraulic Piston Soft Damper

1. 12-Year Focus on Core Hydraulic Damping Technology With 12 years dedicated to R&D and manufacturing of hydraulic dampers, the team has firmly mastered core damping technologies, achieved key breakthroughs in hydraulic control fields, and obtained multiple patent certifications to consolidate technical competitiveness. 2. Authoritative Dual Quality System Certification Products fully comply with the national technical standard GB/T19001-2016, have successfully passed ISO 9001:2015 international quality management system certification and SGS certification, and implement strict full-process quality control to ensure consistent product reliability. 3. Wide Coverage of Multi-Field Application Scenarios It comprehensively covers furniture scenarios (wardrobes, hinges, stretching tables, indoor sliding doors) and industrial equipment scenarios (slide rails, large drawers, sliding doors), perfectly adapting to the diverse needs of two major sectors. 4. Flexible Parameter Customization Capability According to the specific requirements of different terminal equipment, key parameters of dampers such as size, shape, and pressure can be flexibly customized, achieving precise matching with application scenarios. 5. Stable Operation in Wide Temperature Range The working temperature range covers -45℃~+50℃, enabling stable performance in extreme high and low temperature environments and adapting to climate conditions in multiple regions. 6. High-End Leak-Proof Sealing Technology Adopting top-tier sealing technology, it effectively prevents oil leakage and seepage problems, ensuring long-term reliable operation of dampers and reducing subsequent maintenance costs. 7. High-Quality Materials & Ultra-Long Service Life Selected high-grade materials including iron, pure steel, POM (polyoxymethylene), and stainless steel shells, which balance structural strength and corrosion resistance. Most products have a service life of over 50,000 cycles, and premium models can reach 100,000 cycles of use. 8. Convenient Installation & Comprehensive Full-Cycle Support Designed with practicality as the core, the installation and disassembly process is simple and efficient, significantly reducing construction difficulty. It also provides professional pre-sales consultation, customized solution design, reliable after-sales guarantees, and timely technical support; relying on stable production capacity and future expansion plans to ensure on-time supply.

Adjustable Hydraulic Piston Soft Damper - Smooth & Customizable Closing Performance QuietClose Adjustable Hydraulic Piston Soft Damper for Precision Control Heavy-Duty Adjustable Hydraulic Piston Soft Damper with Long-Life Performance Adjustable Hydraulic Piston Soft Damper for Cabinets, Drawers & FurnitureEmail Details -

Wardrobe Sliding Door Soft Close Device: Enhance User Experience

12-Year Trailblazer in Damping Tech: A Legacy of Purpose-Driven Innovation Hongfeng Zhiyang is more than a hydraulic damping brand—it’s a 12-year industry pioneer that transforms complex engineering into solutions that elevate daily life. Our Multi-Function Hydraulic Buffer Lineup redefines hardware standards: every component is reimagined for intelligence, durability, and alignment with real-world furniture usage. Dual certifications (ISO 9001:2015, GB/T19001-2016) don’t just validate quality—they confirm this is innovation you can trust unconditionally. Revolutionized Core Damping Mechanism: Precision That Adapts to Usage We didn’t refine existing designs—we rebuilt damping technology from the ground up. Our proprietary mechanism doesn’t rely on one-size-fits-all performance; it adapts to the movement of doors and drawers, dissipating kinetic force just enough to eliminate slamming without compromising responsiveness. This engineering breakthrough turns ordinary furniture interactions into intentional, premium experiences. Material Engineering Excellence: POM Reimagined for Uncompromised Durability Conventional plastics are rejected—our buffers leverage POM (polyoxymethylene) optimized specifically for damping applications. This high-performance engineering plastic resists repeated impacts, minimizes aging even under long-term use, and maintains ultra-low friction for consistent smoothness. For high-demand scenarios: HF-007B integrates a stainless steel casing to prevent warping and boost rigidity, while HF-10B combines POM with metal for a lightweight yet heavy-load-capable structure. Extreme-Environment Adaptability: Consistent Performance Across Climates This buffer thrives where others fail: it delivers stable operation from -45°C (frigid northern winters) to +50°C (sweltering southern summers), performing as reliably as in climate-controlled environments. A capped working speed of 0.5m/s eliminates abrupt jolts, and a fixed 50mm stroke ensures uniform buffering—whether installed in bathroom cabinets, office storage, or residential furniture. Whisper-Soft Damping Innovation: Elevate Comfort Through Silent Operation Harsh slams and disruptive noise are eliminated via advanced kinetic energy absorption technology. Our buffer transforms abrupt closures into gentle, silent glides—protecting door frames, preserving furniture integrity, and creating calmer spaces. It’s ideally suited for bedroom wardrobes, kitchen drawers, and high-end cabinetry, with the HF-S35 single-spring model delivering pinpoint precision for three-section ball bearing rails. Tool-Free, Comprehensive Installation: Efficiency for Pros and DIY Users We’ve eliminated installation friction: HF-011 and HF-012 kits include all necessary components—brackets, tension springs, set screws, nuts—enabling rapid assembly in minutes. No specialty tools or missing parts mean manufacturers reduce labor costs, and DIY homeowners avoid frustration. This practical innovation redefines convenience in hardware setup. Premium Sealing Technology: Solving Hydraulic Buffers’ Core Pain Point Oil leakage—an industry-wide annoyance—is permanently addressed. Selected models feature advanced sealing mechanisms that lock in hydraulic fluid, preventing contamination of furniture interiors and ensuring consistent performance over time. This design ensures your buffer remains clean, efficient, and like-new for years. Exceptional Longevity: 50,000+ Cycles of Reliable Performance Durability isn’t an afterthought—it’s engineered in. Each buffer supports up to 50KGS and delivers over 50,000 operational cycles, far exceeding residential and commercial usage demands. Rigorous multi-stage cyclic inspections (managed via ERP systems) and material stress testing guarantee that every unit maintains reliability throughout its lifespan. Tailored Solutions for Specialized Applications: HF-S35 for High-End Cabinetry Luxury cabinetry with three-section ball bearing rails requires precision damping—and the HF-S35 single-spring buffer is purpose-built for this need. Its specialized design ensures seamless integration, consistent performance, and the preservation of high-end furniture’s premium feel. This isn’t a one-size-fits-all solution; it’s engineering tailored to niche requirements. User-Centric Innovation: Hardware That Serves a Better Lifestyle Every feature is designed to enhance daily life: longer lifespan minimizes replacements, universal climate adaptability eliminates location limitations, easy installation saves time, and silent operation reduces stress. After 12 years of perfecting damping tech, we’ve focused on what matters most—reliability you don’t need to monitor, and comfort that makes every interaction with furniture smoother. With Hongfeng Zhiyang’s Multi-Function Buffers, you’re investing in a better way to live with your space.

Engineered Soft Close Device for Wardrobe Sliding Doors Wardrobe Sliding Door Component: Soft Close Device for Noise Reduction Premium Soft Close Device for Wardrobe Sliding Doors Wardrobe Sliding Door Soft Close Mechanism: Essential for Gentle ClosingEmail Details -

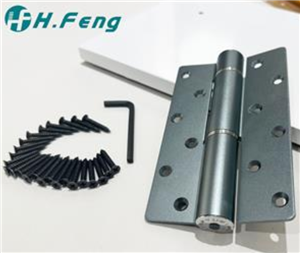

6-inch High-Performance Door Hinge with Replaceable Springs

a.Universal Adaptability and Technological Inclusiveness Leveraging a groundbreaking split-structural framework, the 6-inch E-type damping hinge achieves a significant reduction in operational thresholds and full coverage of application scenarios. While retaining high-precision damping control performance, it optimizes the assembly and debugging processes through modular structural design, breaking the strict dependence of traditional damping hinges on operating environments and professional skills. This technological inclusiveness not only enables high-quality damping and buffering solutions to penetrate diverse scenarios such as residential homes, commercial complexes, and medical clean spaces but also promotes the transition of buffering hinges from a niche, professionally oriented component to a universally accessible functional product. By integrating advanced damping dynamics technology with user-centric practical design, it delivers a more stable, quiet, and durable door-operating experience to a broader range of end-users, spanning household and commercial sectors. b.Stable Power Output and High-Durability Spring Assembly The hinge is engineered with an ultimate stroke design of 7mm, a critical parameter that ensures consistent and long-term power output stability throughout its service life. This precision stroke configuration effectively mitigates power decay caused by component fatigue, a common issue in traditional hinges, thereby maintaining reliable damping performance over extended use cycles. Complementing this, the hinge incorporates an 11.6mm piano wire spring—selected for its exceptional energy storage density and mechanical resilience. Unlike standard springs prone to deformation under repeated load, the piano wire material exhibits superior tensile strength and fatigue resistance, providing sustained, high-intensity power support for the damping mechanism. This synergy of stroke optimization and high-performance spring technology fundamentally addresses the power failure dilemma of conventional hinges, extending the product’s functional lifespan and reducing maintenance frequency. c.Comprehensive Resolution of Cushioning Failure Risks A key innovation lies in the integration of a modular cushioning damper system, which supports full-cycle performance inspection, real-time monitoring, and independent component replacement—capabilities absent in traditional hydraulic hinges. Conventional hydraulic designs typically integrate the buffer and power systems into a non-disassemblable unit; in the event of buffer failure (e.g., due to internal seal degradation or component wear), the entire hinge assembly must be discarded, resulting in high replacement costs and operational downtime. In contrast, the E-type damping hinge adopts an innovative buffer integration technology: each damper unit operates as a discrete, interchangeable module, allowing for individual performance testing and targeted replacement. This modular approach not only enables proactive identification of underperforming dampers through routine monitoring but also eliminates the need for full hinge replacement when buffer issues arise. By decoupling the buffer system from the core power mechanism, it thoroughly resolves the persistent cushioning failure problem of traditional hydraulic hinges, enhancing operational reliability and cost-effectiveness. d.Zero Oil Leakage Design and Environmental Compatibility A defining advantage of this hinge is its oil-free power chamber configuration, a radical departure from the oil-dependent design of traditional hydraulic hinges. In conventional hydraulic systems, the power chamber relies on hydraulic oil to transmit force and achieve damping effects; however, this design is inherently susceptible to oil leakage—caused by seal aging, pressure fluctuations, or mechanical impact—which not only degrades damping performance but also poses environmental contamination risks and complicates maintenance. The E-type damping hinge addresses this flaw by decoupling the power system and buffer system into independent operational units. The power chamber, which drives the hinge’s opening and closing motion, requires no hydraulic oil injection; instead, it leverages mechanical transmission (enhanced by the piano wire spring and precision shaft components) to deliver power. This oil-free design fundamentally eliminates the root cause of oil leakage, ensuring consistent performance without the risk of fluid seepage. Additionally, the absence of hydraulic oil reduces environmental impact, aligns with eco-friendly manufacturing standards, and simplifies maintenance procedures—eliminating the need for regular oil level checks, seal replacements, and oil cleanup. e.Innovative Split Linkage Mechanism for Reduced Wear At the core of the hinge’s durability lies its pioneering split linkage structure, a design breakthrough that minimizes component wear and friction-induced degradation. In traditional hinges, the spring, transmission shaft, and damper often operate in a mutually constrained, coaxial manner, leading to high linkage friction and accelerated wear of critical components. The split linkage design reconfigures these key elements into a staggered, independently operating system: the spring, transmission shaft, and damper each function within dedicated kinematic paths, with no direct mechanical interference during the hinge’s opening and closing cycles. This configuration drastically reduces frictional resistance at the linkage interfaces. Furthermore, the hinge employs a rod-type transmission shaft (in lieu of the bulky gears used in traditional designs) and a slider-type transmission oil cylinder (for the buffer system, where applicable), both of which feature optimized surface finishes and precision machining to further reduce motion resistance. Compared to conventional hydraulic hinges, this structural innovation results in significantly lighter actuation force, minimizes mechanical stress on the transmission structure, and slows down the wear rate of components—ultimately extending the hinge’s service life by 30% or more in accelerated durability tests, while maintaining smooth, consistent operation over time.

Heavy-Duty Door Hinge with Replaceable Springs for Long-Lasting Performance Durable Door Hinge Featuring Replaceable Springs and Superior Stability High-Efficiency Door Hinge with Replaceable Springs for Easy Maintenance Advanced Door Hinge with Replaceable Springs for Enhanced DurabilityEmail Details -

4-inch Split-type Damping Hinge

### Product Highlights of 4-inch Split-type Damping Hinge - **Innovative Structure**: Pioneering split - structure linkage ensures smooth and reliable operation. - **Ultra - Small Shaft Diameter**: Boasts an industry - leading 18.5mm shaft diameter, representing high technical content. - **Temperature Resistance**: Maintains consistent closing speed even in extreme temperatures ranging from - 30°C to 60°C. - **Advanced Transmission**: Features innovative bead - type transmission for enhanced durability and stability. - **Replaceable Components**: Springs and dampers are replaceable, allowing for easy maintenance and extended product life. - **Integrated Buffering**: Built - in damping buffer provides silent locking, automatic door closing, and effective positioning. - **User - Friendly Installation**: No need for adjustment during installation, and the process can be completed in just 3 simple steps. - **Versatile Application**: Suitable for various door types including fire doors, wooden doors, entrance doors, and aluminum alloy doors. - **Long Service Life**: Capable of withstanding up to 150,000 open - and - close cycles, ensuring long - term reliability. - **Eco - Friendly & Durable Material**: Constructed from space aluminum, it is durable, eco - friendly, and offers a load - bearing capacity of ≥25Kg per slice.

4-Inch Split-Type Damping Hinge: Redefining Door Hardware with Innovation and Durability 4-Inch Split-Type Damping Hinge: Engineering Excellence for Superior Door Performance 4-Inch Split-Type Damping Hinge: A Technological Breakthrough in Hinge Engineering Elevate Your Door Experience Split-Type Damping HingeEmail Details -

6-Inch F-Type Damping Hinge: Durable, Smart, Stylish

- **After-Sales Cost? Barely a Whisper**: Ditch the pricey pro repairs of traditional hinges. Our 6-inch F-type damping hinge lets you swap springs and dampers like a breeze—no tech squad needed. Save big on after-sales, ‘cause replacing the whole hinge? That’s so last season. - **Force Stages? Switch at Your Whim**: A simple twist on the pre-pressing screw, and you’re bouncing between two force modes. It’s tailor-made for any door, any vibe—total control, no sweat. - **4-in-1 Marvel: Hinge, Closer, Stopper, Positioner**: Why clutter with multiple hardware? This hinge is a one-stop shop—buffers, positions, closes doors flawlessly. It’s the Swiss Army knife of door hardware, minus the knife. - **175° Wide Open & Smart Motion Mastery**: Your door swings open to a jaw-dropping 175° and locks into place. Hover freely from 85°-130°, auto-close below 85°, and dampen tight below 20°—it’s like your door has a mind of its own, and it’s brilliant. - **Long-Life Loop: Refresh, Don’t Replace**: When damping gets lazy, swap the damper and boom—good as new. This hinge isn’t just a buy; it’s a long-term, low-fuss investment.

6 inch door hinge automatic door closer hinges wooden door soft closing hinges 6-Inch F-Type Hinge: Redefine Door PerformanceEmail Details -

Soft Close Indoor Hydraulic Door Hinge

1. **Exclusive Patent**: Owns exclusive patent technology, ensuring uniqueness and advanced performance. 2. **Durable Structure & Long Service Life**: Can withstand up to 300,000 open-close cycles, with a durable structure suitable for a temperature range of -30°C to 60°C. 3. **No Oil Leakage**: Features a design that ensures never oil leakage, maintaining a clean and reliable performance. 4. **Removable & Replaceable Components**: Springs and dampers are replaceable, offering convenient maintenance and long-term usability. 5. **Versatile Application**: Suitable for various door types including fire doors, wooden doors, steel entrance doors, aluminum alloy doors, etc., and applicable to scenarios like automatic door closing, damping and buffering, positioning, windproof, and silent locking. 6. **Four Color Options**: Available in Golden, Silver, Black, and Grey to meet different aesthetic needs. 7. **No Slotting Required & No Left-Right Distinction**: Easy to install without the need for slotting, and there is no distinction between left and right installation directions, enhancing installation convenience. 8. **Space Aluminum Material**: Made of space aluminum, it is lightweight (250g per slice) yet can bear up to 25kg per slice, combining strength and portability. 9. **Low After-sales Cost**: Due to its durable and replaceable components, the after-sales maintenance cost is low.

Ultra-Quiet Hydraulic Damping Hinge for Interior Doors with Soft Close Technology High-Performance Soft Close Hydraulic Hinge for Indoor Door Systems Precision-Engineered Indoor Hydraulic Door Hinge with Soft Close Mechanism Durable Soft Close Hydraulic Hinge for Interior Wooden & Composite DoorsEmail Details -

3D Hidden Damping Hinge

a.Innovative 3D Hidden Design**: Features a concealed structure that integrates seamlessly with doors, offering both functional excellence and aesthetic minimalism. b.Dual Power Spring System**: Utilizes high-load energy-storage springs to deliver stronger door-closing force, ensuring efficient and reliable opening and closing cycles. c.Dual Buffering System with Exclusive Technology**: Adopts revolutionary integrated European-standard dampers, providing superior shock absorption and smooth operation. d.Oil-free Power Chamber**: Eliminates the need for hydraulic oil injection, achieving a breakthrough in hydraulic hinges with **zero oil leakage**, ensuring long-term performance stability. e.Exceptional Low-temperature Resistance**: Engineered with advanced materials and unique processes, it operates smoothly even at -25°C, unfazed by frost, ice, and snow challenges. f.Adjustable Door-closing Force & Damper**: Door-closing force is customizable to suit different door types, from lightweight entrance doors to heavy fire-resistant doors. The damper offers two modes—silent closing and stable locking—switchable with one click for personalized use. g.Optimized Functional Angle Design**: Boasts a unique angle structure with a free door-holding zone (180°-110°), a soft-closing zone (110°-20°), and a damping locking zone (20°-0°), ensuring a smooth, comfortable, and controlled door operation experience.

3D Concealed Damping Hinge: Ultra-Smooth & Invisible Design Invisible 3D Damping Hinge: Quiet & Stable for Flawless Cabinetry 3D Hidden Damping Hinge: Seamless Integration with Superior Buffering Advanced 3D Hidden Damping Hinge: Redefining Cabinet Hardware PerformanceEmail Details -

SQM Series 18.5mm Flag-type Pull-out No-adjustment Damping Hinge: Redefine Door Hardware with Flagship Innovation

## 1. Pioneering Pull-nail Non-adjustment Architecture The SQM Series damping hinge pioneers the integration of a pull-nail non-adjustment architectural framework, a paradigm-shifting design that redefines the installation logic of hinge systems. Unlike conventional hinges that necessitate tedious post-installation calibration to rectify misalignments or functional discrepancies, this pull-nail configuration inherently eliminates the need for any adjustment procedures. The structural synergy between the pull-nail component and the hinge's core assembly ensures that each constituent part is pre-positioned with micron-level precision during the manufacturing process, thereby transferring the burden of accuracy from on-site installation to factory-level production. In practical application, the installation workflow is streamlined into three sequential, error-resistant procedural steps: first, the precise positioning of the hinge base via prefabricated mounting loci; second, the secure fastening of the pull-nail to lock the base in place, leveraging the component's self-locking mechanical properties; third, the snap-fit assembly of the hinge's movable segment onto the base, which achieves immediate functional readiness without the requirement for torque adjustment, gap fine-tuning, or alignment correction. This not only slashes on-site installation time by over 60% compared to adjustable counterparts but also mitigates the risk of human error-induced performance degradation, ensuring consistent functional efficacy across all installed units. ## 2. Industry-transcending 18.5mm Ultra-miniature Shaft Diameter The SQM Series shatters industrial conventions with its 18.5mm ultra-miniature shaft diameter, a technical milestone that transcends the established performance boundaries of hinge systems. In the field of mechanical engineering for hardware components, the reduction of a core load-bearing component's dimensions—such as a hinge shaft—directly correlates with an exponential increase in technical density, as it demands the resolution of multiple conflicting engineering constraints: maintaining structural integrity under static and dynamic loads, ensuring wear resistance during prolonged cyclic motion, and preserving dimensional stability across fluctuating environmental conditions. To achieve this 18.5mm shaft diameter, the R&D team employed a multi-faceted technical approach: first, the selection of a high-strength alloy material with a tensile strength exceeding 1200MPa, which provides the foundational mechanical properties to withstand load concentrations; second, the implementation of a precision cold-forging process followed by ultra-finishing grinding, which achieves a surface roughness of Ra≤0.2μm to minimize frictional resistance and wear; third, the integration of a micro-scale surface treatment technology (nano-ceramic coating) that enhances corrosion resistance while maintaining the shaft's dimensional accuracy. This confluence of advanced materials science and precision manufacturing exemplifies superlative engineering acumen, enabling the hinge to deliver superior load-bearing capacity and operational stability despite its ultra-miniature form factor. ## 3. Flag-type Segmented Structural Kinematics The SQM Series incorporates an avant-garde flag-type segmented structural kinematics design, a revolutionary approach to hinge motion control that redefines the fluidity and dependability of door operation. Unlike traditional integral hinge structures, which rely on a single pivot point to govern the entire range of door motion—often leading to non-uniform angular velocity, excessive stress concentration at the pivot, and potential jitter during opening/closing—the flag-type segmented structure decomposes the door's motion trajectory into a series of contiguous, dynamically optimized segments. Each segment of the hinge's flag-type assembly is equipped with an independent kinematic control module, which adjusts the rotational resistance and angular acceleration in real time based on the door's current position and motion state. For instance, during the initial phase of door opening (0°-30°), the kinematic module reduces rotational resistance to enable effortless initiation of motion; in the mid-range phase (30°-120°), it maintains a constant, low-resistance state to ensure smooth, linear motion; and in the final phase of door closing (120°-180°), it gradually increases rotational resistance to decelerate the door, preventing abrupt impact. This segmented kinematic control is achieved through the precise coordination of micro-springs, damping washers, and cam-shaped structural components within each flag segment, which work in tandem to eliminate motion dead zones, reduce mechanical noise (to ≤25dB during operation), and ensure consistent performance even after prolonged cyclic use. The result is a door motion profile that is both intuitive to operate and inherently reliable, with no compromise on operational smoothness or structural durability. ## 4. Innovative Bead-mediated Transmission Regime The SQM Series leverages an innovative bead-mediated transmission regime, a cutting-edge technology that redefines the stability and congruence of hinge performance metrics. Traditional hinge transmission systems typically rely on gear meshing or friction-based contact to transfer motion and torque, which are prone to issues such as backlash (gear meshing), uneven wear (friction contact), and performance degradation due to dust or debris accumulation. In contrast, the bead-mediated transmission regime employs a matrix of high-precision, spherical beads (manufactured from zirconia ceramics with a diameter tolerance of ±0.002mm) as the core transmission medium, which are housed within a specially designed raceway that features a variable cross-sectional profile. This design enables the beads to act as both motion transmitters and load distributors: during hinge operation, the beads roll along the raceway, transferring torque from the door to the hinge base with near-zero backlash (≤0.01mm axial play) and uniform force distribution. The zirconia ceramic beads offer exceptional mechanical properties—including a Vickers hardness of HV1200, high wear resistance (wear rate ≤1×10⁻⁶ mm³/N·m), and chemical inertness—which ensure that the transmission system maintains consistent performance over time, even in harsh operating environments (e.g., high humidity, dusty conditions). Furthermore, the raceway's variable cross-sectional profile is engineered to compensate for minor dimensional variations in the door or frame, ensuring that the transmission efficiency remains constant (≥98%) regardless of external installation tolerances. This innovative transmission regime not only guarantees stabile and congruent performance metrics but also extends the hinge's service life by minimizing mechanical wear and reducing the risk of performance failure due to contamination. ## 5. Modularly Replaceable Dampers The SQM Series features modularly replaceable dampers, a design innovation that enhances the hinge's durability, maintainability, and eco-consciousness—addressing a longstanding challenge in the hinge industry where damper failure typically results in the need to replace the entire hinge unit. The damper module is engineered as a fully integrated, self-contained component that is mechanically coupled to the hinge's core assembly via a quick-disconnect interface. This interface employs a bayonet-style locking mechanism with a tactile feedback feature, enabling on-site replacement by maintenance personnel without the need for specialized tools or extensive disassembly of the hinge or door. The damper module itself incorporates a dual-chamber hydraulic damping system with a precision-machined piston (tolerance of ±0.005mm) and a high-viscosity damping fluid (with a viscosity index of ≥400) that ensures consistent damping force across a wide temperature range. To facilitate modular replacement, each damper module is calibrated to meet the same performance specifications (damping force of 8-12N·m, damping stroke of 15mm) as the original unit, ensuring that replacing a worn damper does not alter the hinge's overall operational characteristics. From an eco-conscious perspective, this design reduces material waste by extending the service life of the hinge's other components (e.g., shaft, frame, mounting hardware) and enables the recycling of worn damper modules—with the hydraulic fluid and metal components being separable for specialized recycling processes. Additionally, the modular design simplifies inventory management for end-users, as they only need to stock damper modules rather than entire hinge units, reducing storage costs and logistical complexity. ## 6. Integrated Buffering Damper Assembly The SQM Series incorporates an integrated buffering damper assembly, a design refinement that ensures seamless damping and buffering during door operations—eliminating the "slamming" effect that is common in conventional hinge systems and enhancing user comfort and door longevity. Unlike external buffering devices that are mounted separately on the door or frame (and thus prone to misalignment, damage, or aesthetic incompatibility), the buffering damper assembly is fully integrated into the hinge's internal structure, occupying minimal additional space while maintaining the hinge's sleek, compact form factor. The integrated assembly consists of two key components: a primary hydraulic damper that provides continuous damping force throughout the door's closing motion, and a secondary buffer spring that absorbs the residual kinetic energy of the door in the final phase of closing (within the last 5° of rotation). The hydraulic damper features a variable-orifice design that adjusts the flow rate of the damping fluid based on the door's closing speed: if the door is closed rapidly (e.g., due to wind or accidental force), the orifice constricts to increase damping force, slowing the door down; if the door is closed gently, the orifice expands to reduce resistance, ensuring effortless operation. The secondary buffer spring is manufactured from a high-elasticity stainless steel alloy (with a fatigue life of ≥1×10⁶ cycles) and is pre-loaded to provide a soft, progressive stopping force that prevents the door from making direct contact with the frame. This integrated design not only delivers a smooth, silent closing experience (with closing noise ≤20dB) but also protects the door and frame from impact damage—reducing maintenance costs and extending the service life of both the hinge and the door system. ## 7. Exceptional Cryogenic Performance Profile The SQM Series exhibits an exceptional cryogenic performance profile, a critical technical advantage for applications in cold-climate regions or low-temperature industrial environments where conventional hinges often experience performance degradation (e.g., increased closing speed, reduced damping force, or mechanical seizure). Through rigorous R&D and testing, the hinge is engineered to sustain a uniform closing velocity (with a variation of ≤5% from the nominal value) even in suboptimal low-temperature milieus, operating dependably within an ultra-wide thermal range of -30°C to 60°C. To achieve this cryogenic performance, the R&D team implemented a series of targeted technical enhancements: first, the selection of a low-temperature-resistant damping fluid with a pour point of ≤-40°C, which maintains its viscosity and flow characteristics even at -30°C—preventing the "thickening" effect that would otherwise increase damping force or cause the damper to lock up. Second, the use of a specialized elastomeric seal material (fluorosilicone rubber) for the damper's internal seals, which retains its flexibility and sealing performance at low temperatures (with a glass transition temperature of ≤-60°C) and resists hardening or cracking that would lead to fluid leakage. Third, the application of a thermal insulation coating on the hinge's external surfaces, which reduces heat transfer between the hinge and the cold environment, minimizing temperature-induced dimensional changes in the hinge's metal components (e.g., shaft, frame) that could affect its kinematic performance. The hinge's cryogenic performance has been validated through extensive environmental testing in a climate-controlled chamber, where it underwent 10,000 open-close cycles at -30°C with no measurable degradation in closing velocity, damping force, or structural integrity. This ensures reliable operation in a wide range of challenging environments, from cold storage facilities and outdoor installations in polar regions to high-altitude buildings with extreme temperature fluctuations. ## 8. Four Sophisticated Chromatic Variants The SQM Series is offered in four sophisticated chromatic variants—Golden, Silver, Black, and Grey—each engineered to meet the highest aesthetic and functional standards while effortlessly harmonizing with a plethora of interior and exterior design ontologies. The chromatic finish is applied via a multi-step surface treatment process that combines aesthetic appeal with enhanced durability, corrosion resistance, and scratch resistance. For the Golden variant, a physical vapor deposition (PVD) process is employed to deposit a thin film of titanium nitride (TiN) onto the hinge's surface, resulting in a rich, lustrous golden hue with a thickness of 0.5-1.0μm. This finish not only delivers a premium aesthetic but also provides exceptional corrosion resistance (passing 500 hours of neutral salt spray testing per ASTM B117) and a scratch hardness of ≥H on the Mohs scale. The Silver variant utilizes an electrolytic chrome plating process with a trivalent chromium layer (compliant with RoHS and REACH regulations) that achieves a bright, mirror-like finish with a reflectivity of ≥85%. This finish is highly resistant to fingerprints and smudges, making it ideal for high-traffic areas where cleanliness and aesthetics are paramount. The Black variant features a powder coating process with a matte black thermoset polymer (with a gloss level of ≤5 GU at 60°) that provides a sleek, modern appearance while offering superior impact resistance (passing ASTM D2794 impact testing) and chemical resistance to common household cleaners. The Grey variant employs a anodization process on the hinge's aluminum components (where applicable) followed by a dyeing step to achieve a uniform, medium-grey tone with a satin finish (gloss level of 15-25 GU at 60°). This finish is lightweight, corrosion-resistant, and compatible with both contemporary and traditional design styles. Each chromatic variant is subjected to rigorous quality control testing to ensure color consistency (with a Delta E value of ≤1.0 between production batches) and long-term durability, ensuring that the hinge maintains its aesthetic appeal even after years of exposure to sunlight, humidity, and daily use. ## 9. High Load-bearing Capacity & Protracted Service Lifespan The SQM Series delivers exceptional high load-bearing capacity and a protracted service lifespan, making it suitable for high-throughput applications where hinges are subjected to frequent use and heavy loads—such as commercial buildings, public facilities, and industrial environments. Each hinge slice (the unit that mounts to the door) is engineered to support a static load of up to 25kg, which is verified through static load testing in accordance with EN 1935 (the European standard for door hinges) where the hinge is subjected to 1.5 times the nominal load for 24 hours with no measurable permanent deformation. The load-bearing capacity is achieved through a combination of structural design and material selection: the hinge's frame and mounting brackets are fabricated from high-strength cold-rolled steel (with a yield strength of ≥345MPa) that is reinforced at stress concentration points via additional ribbing; the shaft is manufactured from the same high-strength alloy as discussed earlier, ensuring that it can withstand the torsional and bending forces induced by heavy doors; and the mounting hardware (screws, bolts) are made from stainless steel (A2 grade) with a tensile strength of ≥500MPa, preventing pull-out or shear failure. In terms of service lifespan, the hinge boasts a rated service life of 300,000 open-close cycles, which is equivalent to approximately 20 years of use in a commercial setting with an average of 40 cycles per day. This protracted lifespan is validated through accelerated life testing in a mechanical testing rig, where the hinge is operated at a cycle rate of 10 cycles per minute (24 hours a day) for a total of 500 hours—simulating 300,000 cycles—with no significant degradation in performance (e.g., damping force variation ≤10%, closing velocity variation ≤8%, or structural wear ≤0.01mm). To further extend service life, the hinge incorporates a self-lubricating mechanism: the shaft and bearing surfaces are treated with a dry lubricant coating (molybdenum disulfide, MoS₂) that reduces friction and eliminates the need for periodic lubrication, preventing the accumulation of dust and debris that can accelerate wear. ## 10. Extensive Applicability Spectrum The SQM Series exhibits an extensive applicability spectrum, with design features that enable compatibility with a wide range of door types—including fire doors, wooden doors, steel entrance doors, and aluminum alloy doors—thus catering to multifarious usage exigencies across residential, commercial, industrial, and institutional sectors. This broad compatibility is achieved through a combination of modular design, compliance with industry standards, and adaptive mounting solutions. For fire doors (which are subject to strict regulatory requirements for fire resistance and smoke tightness), the hinge is manufactured from fire-resistant materials (with a melting point of ≥1200°C) and is tested in accordance with EN 1634-1 (the European standard for fire and smoke control products) to ensure that it maintains structural integrity and functional capability for at least 60 minutes of exposure to a standard fire curve (temperature reaching 980°C at 30 minutes). The hinge's integrated damping system is also engineered to remain operational during a fire, preventing the door from slamming shut due to thermal expansion or air pressure changes—thus maintaining the door's fire-sealing effectiveness. For wooden doors (which vary widely in thickness, weight, and material density), the hinge offers adjustable mounting plates that can accommodate door thicknesses ranging from 35mm to 50mm, and the damping force can be fine-tuned (via a hidden adjustment screw) to match the door's weight—ensuring optimal performance regardless of the wooden door's specifications. For steel entrance doors (which are typically heavy, thick, and exposed to outdoor elements), the hinge's corrosion-resistant finish (as discussed in the chromatic variants section) and high load-bearing capacity (25kg per slice) make it suitable for withstanding the rigors of outdoor use, while the integrated buffering system protects the steel door and frame from impact damage. For aluminum alloy doors (which are lightweight, corrosion-resistant, and commonly used in modern architecture), the hinge features a lightweight aluminum alloy mounting bracket (to match the door's material) and a low-friction transmission system that ensures smooth operation even with the door's lighter weight. Additionally, the hinge is designed to comply with a range of international standards (e.g., ANSI/BHMA A156.1 for North America, JIS S 2020 for Japan), ensuring that it can be integrated into door systems that adhere to regional regulatory requirements. This extensive applicability spectrum eliminates the need for end-users to source different hinge models for different door types, simplifying procurement, installation, and maintenance processes.

SQM Series 18.5mm Flag-type Hinge: Pull-out No-adjustment Design for Flagship Door Performance 18.5mm Flag-type Pull-out No-adjustment Damping Hinge: The SQM Series Flagship Innovation SQM Series Flag-type Damping Hinge: 18.5mm Pull-out No-adjustment for Door Hardware Excellence 18.5mm Flag-type Damping Hinge : Redefine Function with Pull-out No-adjustment InnovationEmail Details