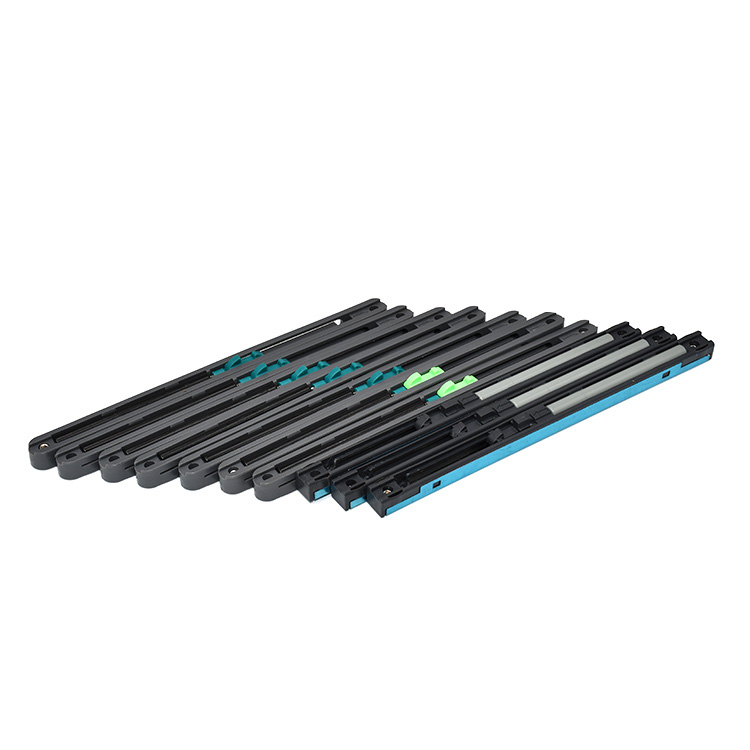

Slide Draw Runner Soft Close Fitting

- WNEE

- CHINA

- 7-15days

- 9999999999999

Rooted in Advanced Material Science: POM-Centric Engineering for Structural Resilience

The series'durability is anchored in polyoxymethylene (POM)—a high-performance engineering polymer selected for its exceptional mechanical rigidity, minimal frictional coefficient, and resistance to impact-induced degradation and long-term aging. For high-stress operational contexts, specialized variants undergo material augmentation: the HF-007B integrates a POM core with a corrosion-inhibiting stainless steel enclosure to mitigate deformation, while the HF-10B employs a heterogeneous POM-metal composite structure to reconcile lightweight design with heavy-duty load-bearing capacity. Supporting components—from ABS brackets to Q235 steel fasteners and SPCC cold-rolled steel fittings—are curated for functional specificity, with holistic system reliability validated via multi-phased cyclic quality audits and ERP-integrated production oversight.

Engineered for Trans-Climatic Operability: Consistent Performance Across Extreme Thermals

Designed to transcend environmental constraints, the series delivers reliable functionality across a -45°C to +50°C thermal spectrum—ensuring efficacy in frigid northern latitudes and sweltering southern climates alike. A regulated operational speed of ≤0.5m/s eliminates abrupt kinetic discontinuities, while a fixed 50mm stroke guarantees uniform damping efficacy across all deployment scenarios. Complemented by a 50KGS maximum load-bearing threshold—exceeding residential and commercial demand parameters—this thermal adaptability positions the series as a versatile solution for geographically diverse markets.

Scenario-Specific Damping Solutions: Elevating User Experience Through Targeted Engineering

The series redefines furniture interaction via application-tailored performance: it enables acoustically attenuated closure of indoor sliding doors to mitigate slamming noise and protect frame integrity, facilitates gentle gliding of large drawers to safeguard internal contents and extend rail lifecycle, and offers the HF-S35 single-spring variant—purpose-built for tri-sectional ball-bearing buffer rails in high-end cabinetry. Its advanced damping mechanism orchestrates precise kinetic energy dissipation, replacing harsh impact forces with seamless, low-acoustic motion that enhances ambient comfort while driving premiumization of end-use furnishings.

Hydrostatic Sealing & Expedited Deployment: Practical Engineering for Real-World Utility

Selected models incorporate hydrostatically sealed configurations to prevent oil leakage and seepage—preserving aesthetic integrity, avoiding furniture contamination, and sustaining consistent damping performance over extended service intervals. For streamlined on-site implementation, variants like the HF-011 and HF-012 are supplied with comprehensive accessory kits (brackets, connectors, tension springs, fasteners) enabling tool-free assembly, which reduces labor cost amortization and installation lead times for both manufacturers and end-users.

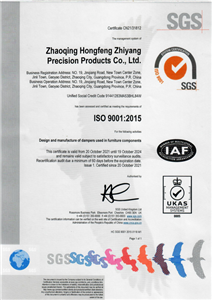

Dual-Certified Quality: Compliance Backed by Rigorous Oversight

Aligned with national GB/T19001-2016 standards and accredited with ISO 9001:2015 certification, the series transcends basic quality benchmarks through a robust quality management framework. Every unit undergoes multi-stage cyclic testing—from material validation to final assembly inspection—overseen via ERP-managed production systems, ensuring that each buffer meets the brand’s stringent performance criteria and resonates with global furniture brands prioritizing reliability.

User-Centric Innovation: Reimagining Daily Furniture Interaction

Beyond technical specifications, the series embodies a paradigm shift in user-furniture engagement: its acoustically attenuated, effort-free closing mechanism transforms routine actions (e.g., drawer closure, door shutdown) into seamless, peaceful experiences. By absorbing kinetic energy at the point of impact, it elevates living and working environments, while the premium tactile feedback of its operation enhances the perceived value of terminal products—positioning the series as a catalyst for smarter, more comfortable spatial design.

Our High-Performance Damper: Engineered for Excellence, Backed by Global Quality Standards

We stand out in the hardware industry by leveraging advanced, internationally calibrated high-precision automated specialized equipment and production lines. Rooted in cutting-edge technology and modern standardized management, our products not only comply with China’s national GB/T19001-2016 technical standards but have also successfully obtained ISO 9001:2015 international quality management system certification—dual endorsements that underscore our uncompromising commitment to quality. Complemented by a strong corporate reputation, sophisticated technical expertise, and an exquisite, rigorous production process, we consistently deliver products that meet and exceed global customer expectations. A shining example of this quality-driven approach is our premium damper, meticulously crafted from a high-performance composite of metal and PC (Polycarbonate). This material pairing is a result of rigorous R&D, designed to balance durability, adaptability, and functionality: the metal component ensures robust structural integrity, capable of withstanding repeated mechanical stress and heavy loads, while the PC material adds superior toughness, thermal stability, and corrosion resistance. This synergy makes the damper versatile across scenarios—from residential furniture (kitchen cabinets, wardrobes, drawers) to commercial spaces (office buildings, retail stores, hotels) and even industrial environments, where reliability under demanding conditions is critical. What truly elevates this damper is its ability to perform flawlessly in extreme environments. With a working temperature range of -45°C to +50°C, it remains stable whether installed in a freezing subarctic warehouse, a sun-scorched desert facility, or a climate-controlled urban office. This broad adaptability eliminates concerns about functional failures due to temperature fluctuations, making it a trusted choice for customers across diverse geographies. In terms of operational precision, the damper excels with a run time of 2–5 seconds and a working speed of 0.5m/s or less. These specifications ensure smooth, silent operation—whether it’s a drawer closing gently in a home kitchen or a cabinet shutting quietly in a busy office—enhancing user experience while reducing wear and tear on both the damper and the equipment it integrates with. Additionally, its maximum bearing capacity of 100GS (Gauss) provides strong resistance to magnetic interference, a key advantage for use near electronic devices, power transformers, or magnetic storage systems—where lesser products may falter. Durability is another cornerstone of our design. Boasting a service life of more than 100,000 cycles, the damper far surpasses industry averages, minimizing replacement needs and lowering long-term costs for customers. For homeowners, this means years of trouble-free use; for businesses, it translates to reduced downtime and maintenance expenses. Every unit of this damper undergoes strict quality checks at every production stage—from raw material inspection (ensuring metal and PC meet our high standards) to final performance testing—all overseen by our automated equipment and standardized management systems. This rigorous process ensures that every product leaving our facility embodies the excellence that has earned us ISO 9001:2015 certification and compliance with national standards. As we continue to innovate, we remain dedicated to delivering hardware solutions that combine reliability, performance, and quality—trusted by customers worldwide.

Material:metal+pc

Working temperature:-45°~+50°

Run time:2~5s

Working speed:0.5m/s or less

The maximum bearing:100GS

Service life:more than 10w times