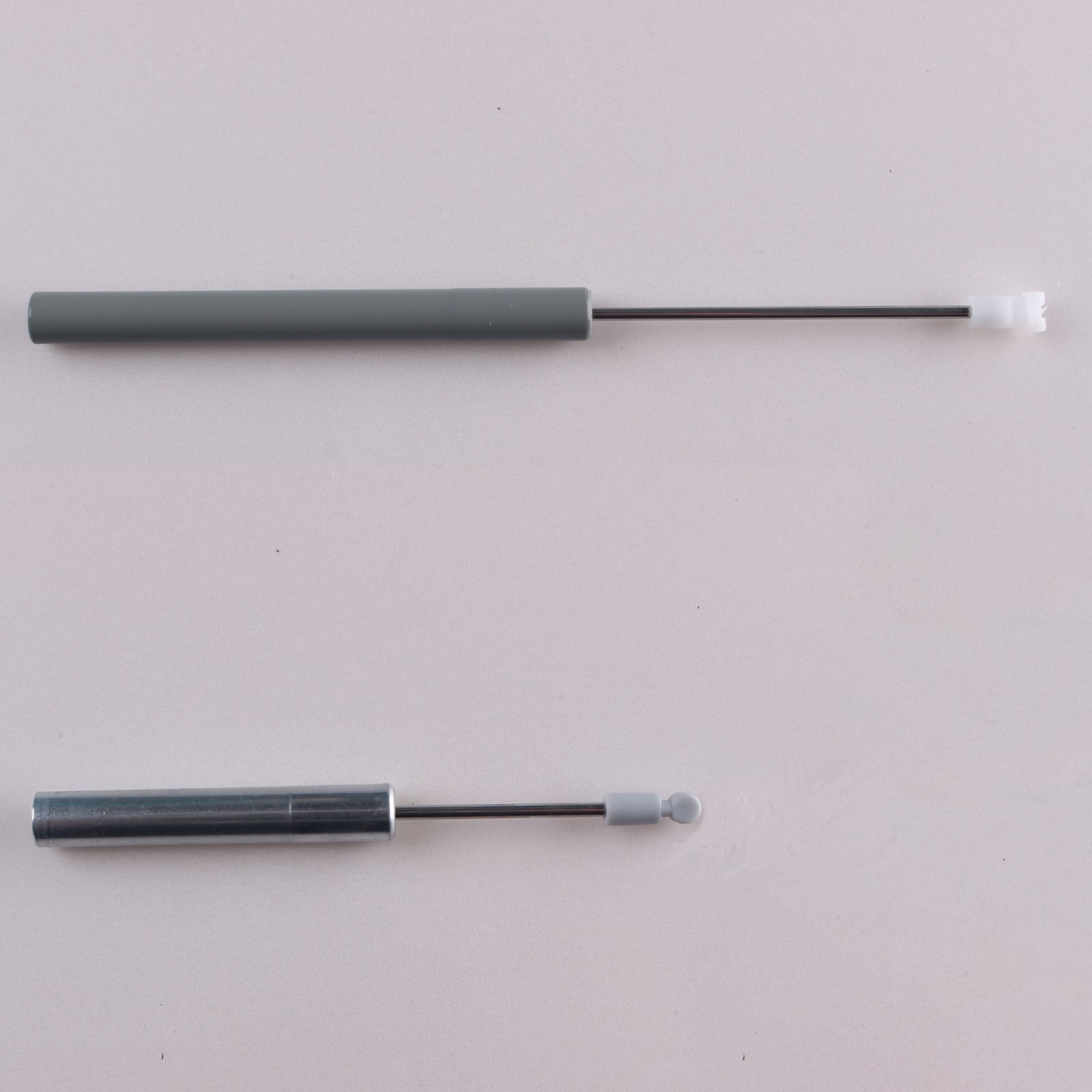

Wardrobe Wooden Door Multifunction Buffer

- WNEE

- CHINA

- 7-15days

- 999999999999999999

1. Core Tech Accumulation, Premium Materials & Long Durability

We dedicate 12 years to the R&D and manufacturing of hydraulic dampers, gaining a firm grasp of core damping technologies, making breakthroughs in hydraulic tech, and securing multiple patents. To ensure long-term reliability, we use a variety of premium materials—including iron, pure steel, POM (polyoxymethylene), and stainless steel shells—that balance structural strength and corrosion resistance for different usage environments. Most products boast an exceptionally long service life of over 50,000 cycles, with some models reaching 100,000 cycles, thanks to their strong durability that cuts down on replacement frequency.

2. Authoritative Quality Certifications & Stable Performance

Our dampers meet the national technical standard GB/T19001-2016, and have passed the ISO 9001:2015 international quality management system certification as well as SGS certification, with strict quality control implemented throughout the entire production process. They also maintain steady performance in extreme conditions: operating across a temperature range of -45℃ to +50℃, they adapt to climate conditions in multiple regions. Plus, high-end sealing technology is adopted to effectively prevent oil leakage and seepage, ensuring reliable long-term operation and reducing maintenance costs.

3. Wide Application, Flexible Customization & Full Support

Covering scenarios like hinges, sliding doors, slide rails, wardrobes, stretching tables, indoor sliding doors, and large drawers, our dampers meet the needs of furniture, industrial equipment, and other fields. Based on specific application scenarios, key parameters—such as size, shape, and pressure—can be tailored flexibly to match different terminal equipment requirements. We also provide mature pre-sales consultation and after-sales guarantee services, along with customized solutions; meanwhile, relying on stable production capacity (and future production capacity upgrade plans), we ensure timely supply.

By providing the best products with the highest level of professional knowledge and market - led innovation technology, we have been making steady progress to gradually become the benchmark that leads and promotes the development of the industry. Our R&D team, composed of experts with decades of experience in the damping and hardware field, continuously delves into cutting - edge technologies. For instance, in the development of our multifunctional buffer dampers, we combined fluid dynamics research with smart material applications, resulting in products that not only have superior performance but also adapt to the intelligent trend of the industry. We also keep a close eye on market dynamics, conducting regular market research and competitor analysis. This allows us to identify emerging needs early, such as the demand for quieter and more energy - efficient damping solutions in modern smart homes, and then launch innovative products that meet these needs ahead of others. Focusing on the needs of customers, we always adhere to the concept of professional and dedicated brand development. We have set up a special customer research department that collects and analyzes customer feedback through multiple channels, including online surveys, offline interviews, and after - sales service records. This helps us gain a deep understanding of their pain points and expectations. Taking our wardrobe door buffers as an example, based on customer feedback about installation difficulties, we optimized the product structure, making it easier to install without compromising performance. Our sales and technical support teams are also trained to be highly professional and responsive, ensuring that they can provide timely and accurate solutions to any customer inquiry, whether it's about product selection, technical parameters, or application scenarios. We are committed to an enterprising attitude, which is embodied in our continuous pursuit of excellence in every aspect of our business. In production, we constantly upgrade our manufacturing equipment and processes, introducing automated production lines and precision testing instruments to improve product consistency and quality stability. In management, we adopt advanced enterprise resource planning (ERP) systems to optimize workflow and resource allocation. Moreover, we encourage a culture of innovation and learning within the company, organizing regular training sessions and technical exchanges to keep our employees at the forefront of industry knowledge and skills. This enterprising spirit has not only helped us gain a strong foothold in the domestic market but also enabled us to expand our presence in international markets, where our products are recognized for their innovation and reliability. Step by step, we are solidifying our position as an industry leader, driving the entire sector towards higher standards of quality, innovation, and customer satisfaction.

Material:metal+pc

Working temperature:-45°~+50°

Run time:2~5s

Working speed:0.5m/s or less

The maximum bearing:100GS

Service life:more than 10w times