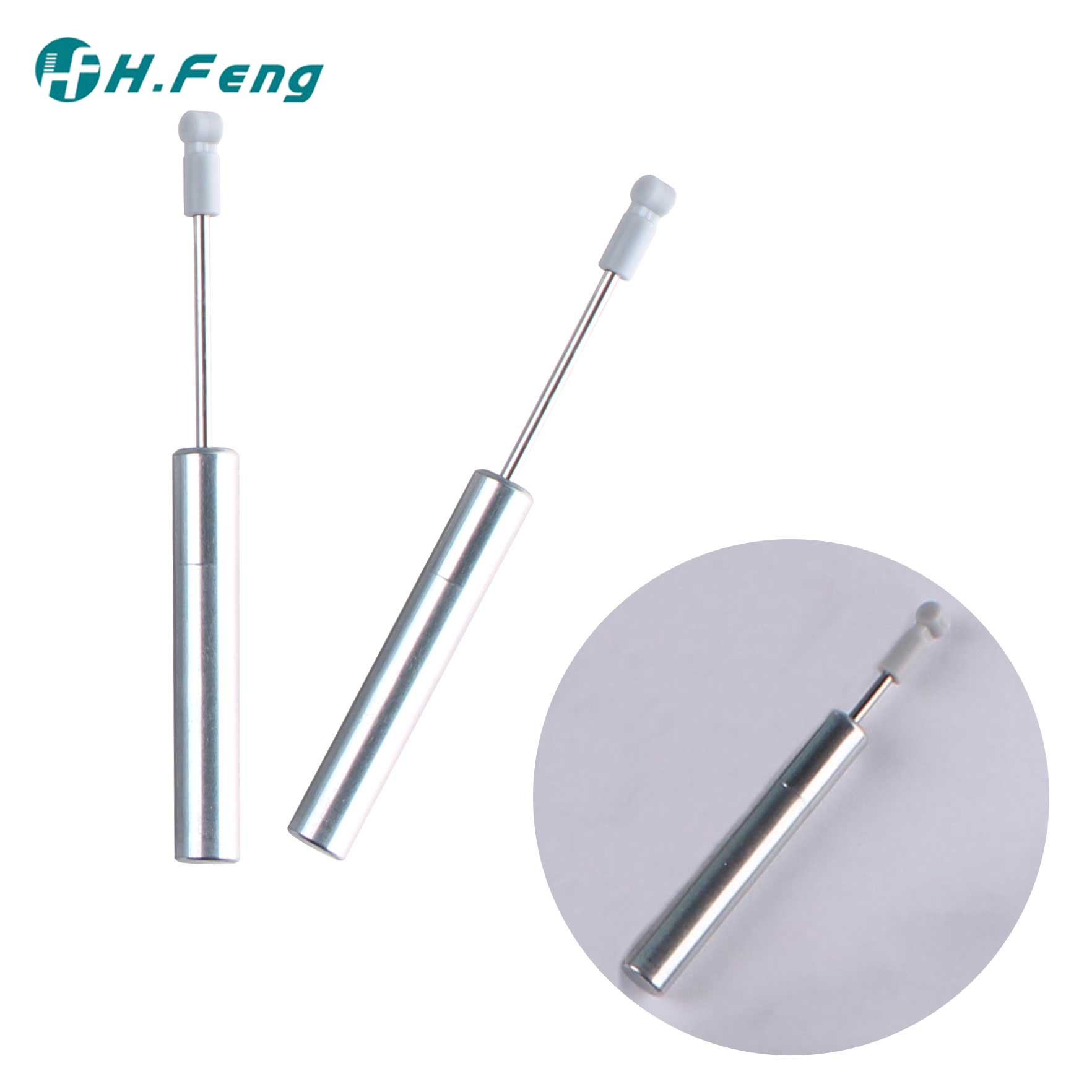

Sliding Door Damper

- WNEE

- CHINA

- 7-15days

- 999999999999999999

1. In-depth Accumulation of Core Technologies

With 12 years devoted to the R&D and manufacturing of hydraulic dampers, the enterprise has mastered core damping technologies. It has also made breakthroughs in the field of hydraulic technology and obtained multiple patents.

2. Authoritative Quality System Certification

The products comply with the national technical standard of GB/T19001-2016, pass the ISO 9001:2015 international quality management system certification as well as SGS certification, and implement strict quality control throughout the entire process.

3. Flexible Customization Capability

According to specific application scenarios, parameters of dampers such as size, shape and pressure can be customized flexibly, so as to meet the requirements of different terminal equipment.

4. Stable Operation in Wide Temperature Range

Covering a working temperature range of -45℃~+50℃, the dampers can maintain stable performance in extreme temperature environments, and adapt to climate conditions in multiple regions.

5. High-end Leak-proof Sealing

High-end sealing technology is adopted to effectively avoid oil leakage and seepage, which ensures the long-term reliable operation of dampers and reduces maintenance costs.

6. Convenient and Efficient Installation & Dismantling

Focusing on practicality in product design, the installation and dismantling process is simple and convenient, which lowers construction difficulty and improves assembly efficiency.

7. Ultra-long Service Life

Most products have a service life of more than 50,000 times, and some models can achieve 100,000 times of use. With strong durability, they help reduce replacement frequency.

8. High-quality and Diverse Material Options

Various quality materials are used, including iron, pure steel, POM (polyoxymethylene) and stainless steel shells. These materials balance strength and corrosion resistance, adapting to different use environments.

9. Wide Coverage of Application Scenarios

It covers scenarios like hinges, sliding doors, slide rails, wardrobes, stretching tables, indoor sliding doors and large drawers, adapting to the needs of furniture, industrial equipment and other fields.

10. Comprehensive Pre-sales and After-sales Support

Mature pre-sales consultation and after-sales guarantee services are provided, and customized solutions can be offered; at the same time, relying on stable production capacity (and future production capacity upgrade plan), timely supply is ensured.

At our company, pragmatism is not just a slogan but a deeply rooted work principle that guides every decision and action. We firmly reject bells and whistles, focusing instead on tangible results and practical value in all operational links. From project development to after-sales service, we emphasize streamlined processes, data-driven decision-making, and efficient problem-solving—refusing unnecessary formalities that waste resources or delay progress. For example, in product R&D, our teams prioritize functional reliability over superficial design, conducting rigorous tests to ensure each component meets real-world application needs rather than chasing aesthetic trends. This pragmatic approach has earned us a reputation for delivering consistent, trustworthy solutions in the industry.